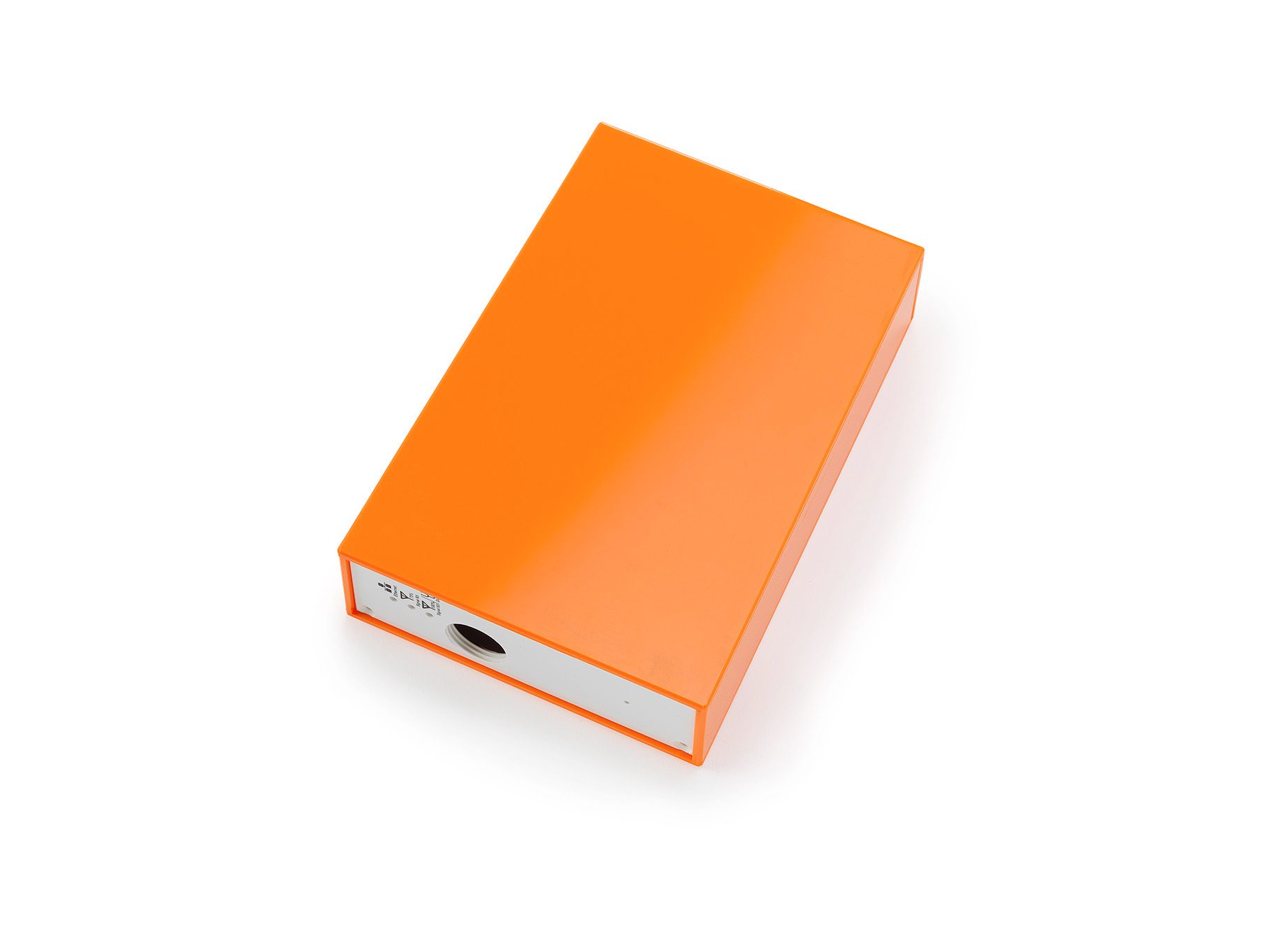

Need a waterproof enclosure for your electrical, marine, industrial or electronics project? Why not consider a custom plastic enclosure from CDT that can withstand the harshest of environments.

Check out our gallery of waterproof enclosure case studies…

Bespoke Raspberry Pi Weatherproof Enclosure

We designed, manufactured and assembled a large order of custom Raspberry Pi weatherproof…

Pole Mounted Waterproof Enclosure

Check out this custom, plastic waterproof enclosure which we manufactured for an existing…

IP Rated Enclosures for Swimming Pools

We were delighted to once again design and manufacture these stylish, wearable, IP…

Weatherproof Plastic Enclosure for EV Charging

Having developed various electric vehicle (EV) charging enclosures over the years, we were…

Why Use Us for your Weatherproof Enclosure?

• close tolerances so parts fit closely together to prevent ingress of solids and liquids

• no MOQs or tooling costs

• cost efficiency for low quantities

• fast turnaround times

• flexibility of design

We work closely with our clients to ensure our custom enclosures are suitably weatherproof or waterproof as required. Also offer UV resistant and flame retardant plastics composites.

Traditionally metal enclosures have been used outdoors as they were considered sufficiently robust and better able to withstand the elements. But increasingly plastic IP rated enclosures are replacing metal ones as the preferred option for electrical or electronics components in outdoor settings like roadsides, marine environments, construction sites, EV charging points, control boxes and automation sensors. This is mainly because they are better suited for transmitting RF.

Advantages of a Plastic vs a Metal Enclosure Outdoors:

- Plastic does not rust or get damaged by moisture in the air and is less likely than metal to react to certain chemicals.

- Custom plastic electrical enclosures are more cost-effective compared to custom metal enclosures.

- Plastic enclosures are simpler to install and modify (for example cutting holes in them as needed), plus they often have mounting pillars integrated into them which can make the installation easier.

- They are also lighter and less bulky making them easier to transport and handle compared to metal ones.

- Certain types of plastic enclosures can provide protection from ultraviolet (UV), particularly useful for areas with high temperatures.

- Lastly, most plastics are electrically insulating (unlike metals which are good conductors) so plastic electrical boxes don’t need to be grounded thus avoiding the extra time and expense involved in grounding an electrical box.

Do note that “plastic” is a broad-ranging term that covers many different materials, including polycarbonates, ABS and HIPS. Plastic has come a long way in recent decades and the use of RFI / ESD / EMC shielding options and UV resistant materials gives more flexibility when delivering a product.

Conversely metal is more fire-resistant compared to plastic and also stronger. It would barely be marked by the IK10 test (the maximum specified in EN 62208 2011) – FYI a typical plastic enclosure would pass IK 7 or 8 (which is like hitting it with a big hammer).

Check out our article on the pros and cons of plastic versus metal enclosures for electrical cabinet enclosures.

See what our enclosures customers say.

What next…

Why not come and visit us at our facilities in Brackley north of London. Be inspired and get ideas for your next waterproof enclosure project. You can see the process in action, meet our team of plastic fabrication experts and browse our extensive product gallery.

Alternatively, we are happy to visit you to find out about your enclosure requirements. Email your CAD file or drawing along with a specification to sales@cdt123.com or call us on 01280 845530 to discuss your requirements. Or contact us via the button below and we will be in touch.

Get a project quote today!

We’ll put together a quote and work with you to get started on your waterproof enclosure project. Let’s build something together!

‘Delighted to recommend plastic enclosure manufacturers, CDT in Brackley. We have been working with Ian and the team for 4 years, designing and building charging racks, chip and pin cradles and the latest being cash till converter. They work to high standards and provide a proactive, professional custom design and build service. Their attention to detail (ATD) is second to none!

We knew what we wanted but after sitting down with the design team at CDT it was clear that their input was invaluable and working together ensured we ended up with more than we had ever imagined.’