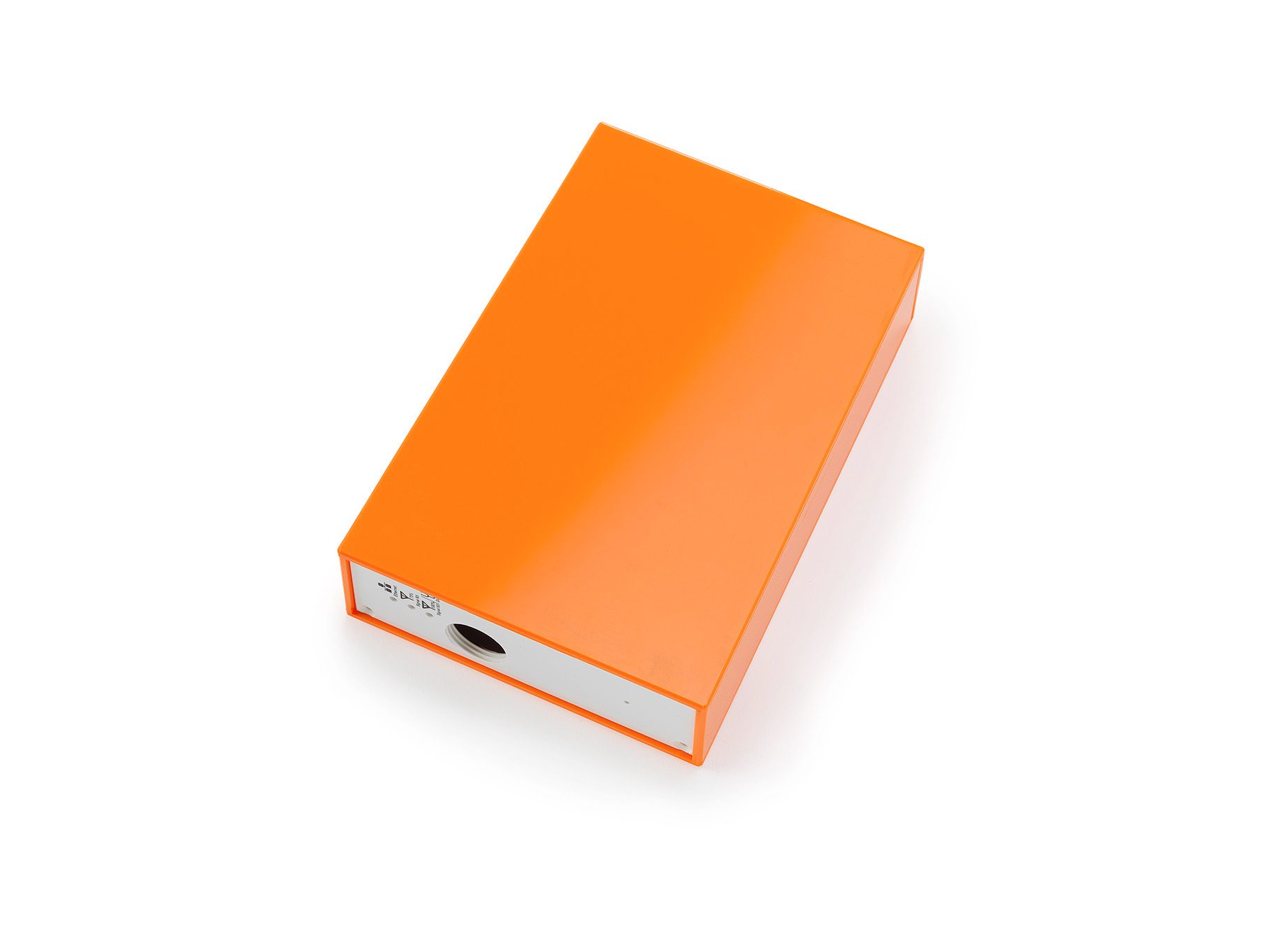

We specialise in IP rated custom plastic enclosures and are well versed in creating waterproof and weather-resistant outdoor enclosures for use in electrical, marine, industrial or electronics projects.

As a leading UK plastic enclosure manufacturer, we can help ensure your next plastic casing or enclosure project meets your waterproofing requirements. Besides our extensive experience with IP rated enclosures, we also offer:

- no minimum order quantities

- no mould tools or restriction on size or quantity that allows you to make changes between production runs

- close tolerances so parts fit closely together to prevent ingress of solids and liquids

- fast turnaround times

- cost-efficiency for prototypes and low quantities

- flexibility of design

- UV resistant and flame retardant plastics composites.

We work closely with our clients to ensure their custom enclosure is suitably weatherproof or waterproof as required. We build to an IP specification and then the client can get the enclosure certified.

Check out our custom waterproof and IP rated enclosure case studies.

Bespoke Raspberry Pi Weatherproof Enclosure

We designed, manufactured and assembled a large order of custom Raspberry Pi weatherproof…

Pole Mounted Waterproof Enclosure

Check out this custom, plastic waterproof enclosure which we manufactured for an existing…

IP Rated Enclosures for Swimming Pools

We were delighted to once again design and manufacture these stylish, wearable, IP…

Weatherproof Plastic Enclosure for EV Charging

Having developed various electric vehicle (EV) charging enclosures over the years, we were…

What IP Rating Enclosure to Use?

Where and how your plastic enclosure or casing is used will determine the degree of weatherproofing needed or the level of IP rating required. Often outdoor electronic housing units will specify a minimum IP rating of IP65, IP66, IP67 – or possibly even IP68 depending on the application.

We design and manufacture enclosures to achieve the required IP rating. We are able to produce outdoor enclosures that can withstand the harshest of environments. They are used for everything from mesh networks, to outdoor control boxes, to oil rigs and even underwater cameras.

What does IP Rating Mean?

IP (or Ingress Protection) rated is defined in international standard EN 60529 and used to define levels of sealing effectiveness, or the degree of protection an object has against intrusion from foreign bodies (tools, dirt etc) and moisture (level of water resistance).

The IP code is used to clarify the capabilities of plastic enclosures instead of using ambiguous terms like ‘waterproof’ or ‘dustproof’. It’s made up of two numbers, the first is the ingress protection against solid objects, and the second details ingress protection against liquids, for example, IP68. The higher the numbers, the higher the sealing effectiveness and degree of protection.

For more information check out our IP Rating System article which details what the IP rated numbers mean.

What Next…

Why not come and visit us at our facilities in Brackley north of London. Be inspired and get ideas for your next waterproof enclosure project. You can see the process in action, meet our team of plastic fabrication experts and browse our extensive product gallery. Alternatively, we are happy to visit you to find out about your enclosure requirements.

Email your CAD file or drawing along with a specification to sales@cdt123.com. or call (01280) 845530 or contact us.

Get a project quote today

We’ll put together a customised quote for your enclosure project. We work with you to create an IP rated enclosure that fits your requirements. Let’s build something together!

‘Delighted to recommend plastic enclosure manufacturers, CDT in Brackley. We have been working with Ian and the team for 4 years, designing and building charging racks, chip and pin cradles and the latest being cash till converter. They work to high standards and provide a proactive, professional custom design and build service. Their attention to detail (ATD) is second to none!

We knew what we wanted but after sitting down with the design team at CDT it was clear that their input was invaluable and working together ensured we ended up with more than we had ever imagined.’